|

| A sketched concept of a shop display |

You've heard the expression before, "the devil is in the detail". Why do we say that? Actually it was a different phrase before that according to Wikipedia, but in general the phrase means that the job being completed needs to be thorough. Depending n the scope of the project, in can be quite a tedious task to make sure that all the details needed are there. When it comes to engineering manufacturing and design, design and details are almost all that matter after you're through the concept phase.

"How are we going to make that?"

The concept design is complete - the render is done and the customer is happy. The concept is passed on to the detail designer and they say to themselves "How are We going to Make that?". It's one of the challenges and also the benefits of design work - not just coming up with something that the customer likes, but then working out how everything will go together, what materials to use and what processes to use for manufacture. To define processes there needs to be documentation in written form, or outlined on the design information supplied to the manufacturer.

|

| Render from a 3D CAD model |

The last point there is what I want to focus on - Times are changing, but mostly the detailing is shown on a 2D drawing. This is the documentation that is sent off for quote and finally further details are added for manufacture. At one company I worked for, part of the process was doing a quote drawing by hand. We had a 2D CAD system but I guess it was the Design Manager's way of doing it quickly.

The hand sketch was done on a typical border representative of the company's standard and the sketch tended to be pretty simple - it might be a rectangle with some holes of similar size drawn on it with dimensions so a fabricator could come back with a quote - just a overall sizes, material, "X" number of holes and quantity. Enough information that the manufacturer could come back with the pricing.

For some companies, the manufacturing drawing shows the supplier that you know what you're doing and what you want.

|

| Weldment and steel detailing with welding notes |

If the drawing looks professional, laid out correctly, all the details and finishes required - it shows your customers that you are professional. I mentioned 2D earlier - 2D drawings and detailing used to be done by hand, then onto a CAD system where vector lines were used and today 3D in many flavours is being used in many organisations. BUT we still rely on those 2D drawings.

3D CAD makes 2D easier

With 3D solid modelling there's no need to do some of the traditional things we used to do like project lines from view to view to get the picture of the top side and isometric "3D" view.

|

| 3D Solid Model |

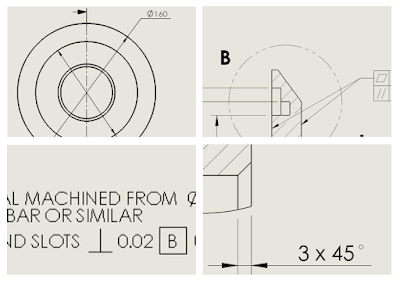

There's minimal guess work. You're able to concentrate on the design and import dimensions or use smart functions to quickly get the detail you need for manufacture. The point is that advanced as our systems are you need to be able to put the right information into a drawing for manufacture. Eliminate duplicates, don't cross lines, space things evenly so that when your drawing is read, it's clear and concise and easy to follow.

|

| Detailing on a 2D drawing sheet

The services HENRY design provides are from concept through to manufacturing drawings, but our "sweet spot" is in that design and detail phase. We take a design that is being developed, partially complete, or "almost there". We work together with you and add the detail as needed to create documentation and drawing packages ready for manufacture. If you'd like to discuss our range of services, please contact us through this link.

|

No comments:

Post a Comment

Feel free to comment - you're ideas help me improve and design new content